Izinto eziluhlaza zezinto ezidibeneyo ziquka i-resin, i-fiber kunye ne-core material, njl.Kukho ukhetho oluninzi, kwaye impahla nganye inamandla ayo ahlukeneyo, ukuqina, ukuqina kunye nokuzinza kwe-thermal, kunye neendleko kunye nemveliso nazo zihluke.

Nangona kunjalo, izinto ezidibeneyo zizonke, ukusebenza kwayo kokugqibela akuhambelani kuphela ne-resin matrix kunye nemicu (kunye neyona nto ingundoqo kwisakhiwo sesandwich), kodwa ihambelana ngokusondeleyo kwindlela yoyilo kunye nenkqubo yokuvelisa izinto kwisakhiwo. .

Eli nqaku liza kwazisa iindlela zokuvelisa ezisetyenziswa ngokuqhelekileyo, ezona nkalo zinempembelelo kwindlela nganye kunye nendlela yokukhetha izinto eziluhlaza kwiinkqubo ezahlukeneyo.

Inkcazo yendlela:Inkqubo yokubumba apho i-fiber eqoshiwe iqiniswe izinto kunye nenkqubo ye-resin ifafazwe kwi-mold ngexesha elifanayo, kwaye iphiliswe phantsi koxinzelelo oluqhelekileyo ukwenza imveliso ye-thermosetting composite.

ukhetho lwezinto:

I-resin: ikakhulu i-polyester

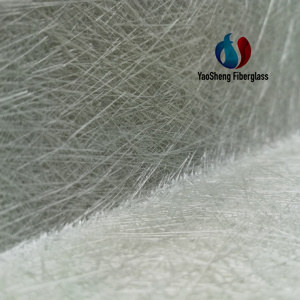

Ifayibha: umsonto orhabaxa wefiber

Izinto ezingundoqo: Akukho, kufuneka kudityaniswe ne-laminates ngokwahlukeneyo

Olona ncedo luphambili:

1) Ubugcisa bunembali ende

2) Ixabiso eliphantsi, ifayibha ekhawulezayo kunye nokubeka i-resin

3) Ixabiso eliphantsi lokungunda

Izinto ezingeloncedo eziphambili:

1) Ibhodi elaminethiweyo kulula ukwenza indawo ephuculweyo ye-resin, kwaye ubunzima buphezulu

2) Iifiber ezinqunqiweyo kuphela zingasetyenziselwa, ezinciphisa kakhulu iipropati ze-mechanical of laminates

3) Ukuze kube lula ukutshiza, i-resin viscosity kufuneka ibe phantsi ngokwaneleyo ukulahlekelwa ngumatshini kunye neempawu zokushisa zezinto ezidibeneyo.

I-4) Umxholo ophezulu we-styrene kwi-resin yokutshiza uthetha ubungozi obuphezulu kubaqhubi, kwaye i-viscosity ephantsi ithetha ukuba i-resin kulula ukungena kwiingubo zokusebenza zabasebenzi kwaye uqhagamshelane ngokuthe ngqo nolusu.

I-5) Ukuxinwa kwe-styrene eguquguqukayo emoyeni kunzima ukuhlangabezana neemfuno zomthetho

isicelo esiqhelekileyo:

Ucingo olulula, iiphaneli zesakhiwo somthwalo ophantsi onje ngemizimba yemoto eguqulwayo, iilori zeelori, iibhafu kunye nezikhephe ezincinci.

Inkcazo yendlela:Yifake ngesandla imicu ngeresin.Iintsinga zinokuqiniswa ngokuluka, ukuphotha, ukuthunga okanye ukudibanisa.Ukubekwa kwezandla ngokuqhelekileyo kwenziwa ngee-roller okanye iibrashi, kwaye ke i-resin igxininiswe nge-rubber roller ukuze ingene kwiifibers.I-laminates yaphiliswa phantsi koxinzelelo oluqhelekileyo.

ukhetho lwezinto:

I-resin: akukho mfuneko, i-epoxy, i-polyester, i-polyvinyl ester, i-phenolic resin yamkelekile

Ifayibha: Akukho mfuneko, kodwa ifayibha ye-aramid enobunzima obukhulu besiseko kunzima ukungena ngokubeka isandla

Izinto eziphambili: akukho mfuneko

Olona ncedo luphambili:

1) Ubugcisa bunembali ende

2) Kulula ukufunda

3) Ukuba i-resin yokunyanga ukushisa kwegumbi isetyenzisiweyo, ixabiso lokubumba liphantsi

4) Ukukhetha okukhulu kwezinto kunye nababoneleli

5) Umxholo wefiber ophezulu, iifiber ezisetyenzisiweyo zide kunenkqubo yokutshiza

Izinto ezingeloncedo eziphambili:

1) Ukuxuba i-resin, umxholo we-resin kunye nomgangatho we-laminates uhambelana ngokusondeleyo nobuchule babaqhubi, kunzima ukufumana i-laminates kunye nomxholo ophantsi we-resin kunye ne-porosity ephantsi.

2) Iingozi zempilo kunye nokhuseleko lwe-resin.Okukhona usezantsi ubunzima bemolekyuli ye-resin yokubeka isandla, kokukhona ubungozi obunokubakho kwimpilo.I-viscosity ephantsi, kulula ukuba i-resin ingene kwiimpahla zokusebenza zabasebenzi kwaye iqhagamshelane ngqo nolusu.

3) Ukuba izixhobo zokungenisa umoya ezilungileyo azifakwanga, ukuxinwa kwe-styrene evuzayo ukusuka kwi-polyester kunye ne-polyvinyl ester emoyeni kunzima ukuhlangabezana neemfuno zomthetho.

I-4) I-viscosity ye-resin yokubeka isandla kufuneka ibe phantsi kakhulu, ngoko umxholo we-styrene okanye ezinye i-solvents kufuneka ube phezulu, ngaloo ndlela ulahlekelwa yimpahla yomatshini / yokushisa yezinto ezidibeneyo.

Usetyenziso oluqhelekileyo:amagqabi einjini yomoya asemgangathweni, izikhitshane eziveliswe ngobuninzi, imifuziselo yoyilo

Inkcazo yendlela:Inkqubo yebhegi yokucoca isandiso senkqubo yokubeka izandla ekhankanywe ngasentla, oko kukuthi, umaleko wefilimu yeplastiki itywinwe kwi-mold ukuze ucoce i-laminate ebekwe ngesandla, kwaye uxinzelelo lwe-atmospheric lusetyenziswa kwi-laminate ukufezekisa. umphumo wokukhupha kunye nokudibanisa.Ukuphucula umgangatho wezinto ezidibeneyo.

ukhetho lwezinto:

I-resin: ikakhulu i-epoxy kunye ne-phenolic resin, i-polyester kunye ne-polyvinyl ester ayifanelekanga kuba iqulethe i-styrene, eguqukayo kwimpompo yokucoca.

Ifayibha: Akukho mfuneko, kwaneentsinga ezinobunzima obukhulu zinokumanziswa phantsi koxinzelelo

Izinto eziphambili: akukho mfuneko

Olona ncedo luphambili:

1) Unokufezekisa umxholo wefayibha ephezulu kunenkqubo eqhelekileyo yokubeka izandla

2) I-porosity iphantsi kunenkqubo eqhelekileyo yokubeka izandla

3) Ngaphantsi kwemeko yoxinzelelo olubi, ukuhamba ngokupheleleyo kwe-resin kuphucula iqondo lokumanzisa imicu.Ngokuqinisekileyo, inxalenye ye-resin iya kuxutywa yi-vacuum consumables

I-4) Impilo kunye noKhuseleko: Inkqubo yesikhwama se-vacuum inokunciphisa ukukhululwa kwee-volatiles ngexesha lokunyanga

Izinto ezingeloncedo eziphambili:

I-1) Iinkqubo ezongezelelweyo zonyusa iindleko zabasebenzi kunye nezixhobo ze-vacuum vacuum ezilahlayo

2) Iimfuno eziphezulu zobugcisa kubaqhubi

3) Ukulawulwa kokuxuba i-resin kunye nomxholo we-resin ubukhulu becala kuxhomekeke kubuchule bomqhubi

I-4) Nangona isikhwama se-vacuum sinciphisa ukukhululwa kwezinto eziguqukayo, ingozi yempilo kumqhubi isephezulu kuneyo yokufakelwa okanye inkqubo ye-prepreg.

Usetyenziso oluqhelekileyo:izikhephe ezinkulu, zexesha elinye elilinganiselweyo, iiyacht zomdyarho, iintambo zomdyarho, ukudityaniswa kwezinto ezingundoqo ekwakhiweni kweenqanawa

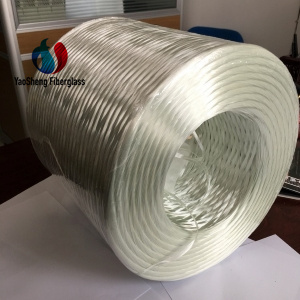

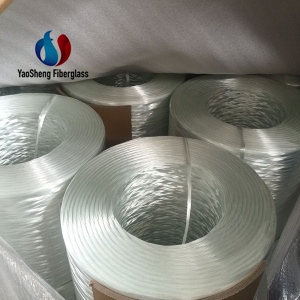

Deyang Yaosheng Composite Material Co., Ltd.yinkampani yobuchwephesha evelisa iimveliso ezahlukeneyo zefiber zeglasi.Inkampani ivelisa ikakhulu i-Fiberglass roving, i-glass fiber inqunqwe i-strand mat, ilaphu le-glass fiber / ilaphu elijikelezayo / ilaphu laselwandle, njl. Nceda uqhagamshelane nathi.

Umnxeba: +86 15283895376

Whatsapp: +86 15283895376

Email: yaoshengfiberglass@gmail.com

Inkcazo yendlela:Inkqubo yokujija isetyenziselwa ukwenza iindawo ezingenanto, ezingqukuva okanye ezimbhoxo njengemibhobho namatanki.Emva kokuba inyanda ifayibha ifakwe resin, inxeba kwi mandrel kumacala ahlukeneyo, kwaye inkqubo ilawulwa ngumatshini wokujija kunye nesantya mandrel.

ukhetho lwezinto:

I-resin: akukho mfuneko, njenge-epoxy, i-polyester, i-polyvinyl ester kunye ne-phenolic resin, njl.

Ifayibha: akukho mfuneko, sebenzisa ngokuthe ngqo i-fiber bundle ye-creel, akukho mfuneko yokuluka okanye ukuthunga kwilaphu lefayibha.

Izinto ezingundoqo: akukho mfuneko, kodwa ulusu luhlala luyinto enye edibeneyo

Olona ncedo luphambili:

I-1) Isantya semveliso sikhawuleza, kwaye yindlela yoqoqosho kunye nengqiqo yokubeka

2) Umxholo we-resin unokulawulwa ngokulinganisa inani le-resin ethwalwa yi-fiber bundle edlula kwitanki ye-resin.

3) Nciphisa iindleko zefayibha, akukho nkqubo yokuluka ephakathi

I-4) Ukusebenza kolwakhiwo kugqwesileyo, kuba imiqulu yefiber enemigca inokubekwa kwiindlela ezahlukeneyo zokuthwala umthwalo.

Iintsilelo eziphambili:

1) Le nkqubo inqunyelwe kwizakhiwo ezijikelezayo ezingenanto

2) Iifiber azilula ukuba zilungelelaniswe ngokuchanekileyo kunye nolwalathiso lwe-axial yecandelo

3) Iindleko ze-mandrel male ngundo kwiindawo ezinkulu zesakhiwo ziphezulu kakhulu

I-4) Umphandle wangaphandle wesakhiwo awukho i-mold surface, ngoko ke i-aesthetics impofu

5) Xa usebenzisa i-resin-viscosity ephantsi, ingqalelo kufuneka ihlawulwe ekusebenzeni kweekhemikhali kunye nempilo kunye nokusebenza kokhuseleko.

Usetyenziso oluqhelekileyo:iitanki zokugcina imichiza kunye nemibhobho yokuhambisa, iisilinda, iitanki zokuphefumla zomlilo

Inkcazo yendlela:I-fiber bundle ethathwe kwi-creel ifakwe kwaye idluliselwe kwi-plate yokufudumeza, kwaye i-resin ifakwe kwi-fiber kwi-plate yokufudumala, kwaye umxholo we-resin ulawulwa, kwaye ekugqibeleni izinto zinyangwa kwimilo efunekayo;le mveliso enyangisiweyo imile ngokomatshini isiya kubude obahlukeneyo.IiFibers zinokungena kwipleyiti eshushu kwicala elingaphandle kwe-0 degrees.

I-Pultrusion yinkqubo yokuvelisa eqhubekayo, kwaye i-cross-section yemveliso ngokuqhelekileyo inesimo esisisigxina, esivumela utshintsho oluncinci.Lungisa izinto ezimanzi ngaphambili ezidlula kwipleyiti eshushu kwaye usasaze kwi-mold ukuze uphiliswe ngokukhawuleza.Nangona le nkqubo inokuqhubeleka kakubi, inokutshintsha imilo yecandelo elinqamlezayo.

ukhetho lwezinto:

I-resin: ngokuqhelekileyo i-epoxy, i-polyester, i-polyvinyl ester kunye ne-phenolic resin, njl.

Ifayibha: akukho mfuneko

Izinto ezingundoqo: aziqhelekanga ukusetyenziswa

Olona ncedo luphambili:

1) Isantya sokuvelisa siyakhawuleza, kwaye yindlela eyongayo nenengqiqo yokumanzisa kwangaphambili kunye nokunyanga izinto.

2) Ukulawulwa ngokuchanekileyo komxholo we-resin

3) Nciphisa iindleko zefayibha, akukho nkqubo yokuluka ephakathi

I-4) Ukusebenza kakuhle kolwakhiwo, kuba iinyanda zefiber zicwangciswe ngendlela ethe tye kwaye iqhezu lomthamo wefiber liphezulu.

I-5) Indawo yokungena kwi-fiber ingavalwa ngokupheleleyo ukunciphisa ukukhululwa kwee-volatiles

Izinto ezingeloncedo eziphambili:

I-1) Le nkqubo inciphisa imilo ye-cross-sectional shape

2) Iindleko zeplate yokufudumeza ziphezulu

Usetyenziso oluqhelekileyo:Imiqadi kunye neetrasi zezakhiwo zendlu, iibhulorho, iileli kunye neecingo

6. I-Resin Transfer Molding (RTM)

Inkcazo yendlela:Beka imicu eyomileyo kwi-mold ephantsi, faka uxinzelelo kwangaphambili ukuze wenze iifiber zilungele ukuma kwe-mold kangangoko kunokwenzeka, kwaye zibophe;emva koko, lungisa i-mold ephezulu kwi-mold ephantsi ukwenza i-cavity, kwaye emva koko ugalele i-resin kwi-mold cavity.

Ivacuum incedise inaliti yeresin kunye nokungeniswa kwefibers zidla ngokusetyenziswa, ezizezi, inkqubo yevacuum assisted resin infusion process (VARI).Nje ukuba i-fiber infiltration igqityiwe, ivalve ye-resin introduction valve ivaliwe kwaye i-composite iyaphiliswa.Isitofu se-resin kunye nokunyanga kunokwenziwa kwindawo yokushisa okanye phantsi kweemeko ezishushu.

ukhetho lwezinto:

I-resin: ngokuqhelekileyo i-epoxy, i-polyester, i-polyvinyl ester kunye ne-phenolic resin, i-bismaleimide resin ingasetyenziswa kwiqondo lokushisa eliphezulu.

Ifayibha: Akukho mfuneko.Iifiber ezithungelweyo zifanelekile ngakumbi kule nkqubo kuba izithuba zefiber bundle ziququzelela ukuhanjiswa kwe-resin;kukho iintsinga eziphuhliswe ngokukodwa ukuququzelela ukuhamba kwe-resin

Izinto eziphambili: I-foam ye-honeycomb ayifanelekanga, kuba iiseli ze-honeycomb ziya kuzaliswa nge-resin, kwaye uxinzelelo luya kubangela ukuba i-foam iwa.

Olona ncedo luphambili:

1) I-fiber volume fraction ephezulu kunye ne-porosity ephantsi

2) Ekubeni i-resin itywinwe ngokupheleleyo, isempilweni kwaye ikhuselekile, kwaye indawo yokusebenza icocekile kwaye icocekile.

3) Ukunciphisa ukusetyenziswa kwabasebenzi

4) Amacala angaphezulu nasezantsi ecandelo lolwakhiwo ziindawo zokungunda, ezilula kunyango lomphezulu olulandelayo.

Iintsilelo eziphambili:

1) Ukubumba okusetyenziswe kunye kuyabiza, kwaye ukuze kuxhaswe uxinzelelo olukhulu, kunzima kwaye kunzima.

2) Kukhawulelwe ekwenziweni kwamacandelo amancinci

I-3) Iindawo ezingenamanzi zivame ukubonakala, zibangele ubuninzi be-scrap

Usetyenziso oluqhelekileyo:isiphekepheke esincinci nesintsokothileyo esisesithubeni kunye neendawo zemoto, izihlalo zikaloliwe

7. Ezinye iinkqubo ze-perfusion - SCRIMP, RIFT, VARTM, njl.

Inkcazo yeNdlela:Beka imicu eyomileyo ngendlela efanayo kwinkqubo ye-RTM, uze ubeke ilaphu lokukhulula kunye nomnatha wokukhupha amanzi.Emva kokuba i-layup igqityiwe, ivalwe ngokupheleleyo ngesikhwama se-vacuum, kwaye xa i-vacuum ifikelela kwimfuno ethile, i-resin ingeniswa kwisakhiwo sonke se-layup.Ukuhanjiswa kwe-resin kwi-laminate kufezekiswa ngokukhokela ukuhamba kwe-resin ngomnatha wesikhokelo, kwaye ekugqibeleni imicu eyomileyo ifakwe ngokupheleleyo ukusuka phezulu ukuya phezulu.

ukhetho lwezinto:

I-resin: ngokuqhelekileyo i-epoxy, i-polyester, i-polyvinyl ester resin

Ifayibha: Nayiphi na ifayibha eqhelekileyo.Iintsinga ezithungelweyo zilungele le nkqubo njengoko izikhewu zefiber bundle zikhawulezisa ukuhanjiswa kweresin

Izinto eziphambili: igwebu lobusi alisebenzi

Olona ncedo luphambili:

I-1) Iyafana nenkqubo ye-RTM, kodwa icala elinye kuphela yindawo yokubumba

I-2) Elinye icala le-mold yisikhwama se-vacuum, esigcina kakhulu iindleko ze-mold kunye nokunciphisa imfuno yokubumba ukumelana noxinzelelo.

I-3) Iindawo ezinkulu zesakhiwo nazo zinokuba neqhekeza eliphezulu le-fiber volume kunye ne-porosity ephantsi

I-4) I-mold ye-standard hand-up process mold ingasetyenziselwa le nkqubo emva kokuguqulwa

5) Isakhiwo sesandwich sinokubunjwa ngexesha elinye

Izinto ezingeloncedo eziphambili:

1) Kwizakhiwo ezinkulu, inkqubo inzima kakhulu, kwaye ukulungiswa akunakugwenywa

2) I-viscosity ye-resin kufuneka ibe yinto ephantsi kakhulu, ekwanciphisa iimpawu zomatshini

I-3) Iindawo ezingenamanzi zivame ukubonakala, zibangele ubuninzi be-scrap

Usetyenziso oluqhelekileyo:Ukuveliswa kovavanyo lweenqanawa ezincinci, iipaneli zomzimba zoololiwe kunye neelori, ii-wind turbine blades

8. Prepreg - inkqubo ye-autoclave

Inkcazo yendlela:I-fiber okanye i-fiber cloth ifakwe ngaphambili ngumenzi wezinto eziphathekayo kunye ne-resin equkethe i-catalyst, kwaye indlela yokuvelisa iqondo lokushisa eliphezulu kunye nendlela yoxinzelelo oluphezulu okanye indlela yokuchithwa kwe-solvent.I-catalyst i-latent kwiqondo lokushisa, inika izinto eziphathekayo kwishelufu yeeveki okanye iinyanga kwiqondo lokushisa;ifriji inokwandisa ubomi bayo beshelufu.

I-prepreg inokubekwa ngesandla okanye umatshini phezu komngundo, emva koko ugqunywe kwingxowa yokufunxa kwaye ufudunyezwe ukuya kwi-120-180 ° C.Emva kokufudumeza i-resin inokuhamba kwakhona kwaye ekugqibeleni inyange.I-autoclave ingasetyenziselwa ukufaka uxinzelelo olongezelelweyo kwizinto eziphathekayo, ngokuqhelekileyo ukuya kwi-5 atmospheres.

ukhetho lwezinto:

I-resin: ihlala i-epoxy, i-polyester, i-phenolic resin, i-resin ephezulu yokumelana nobushushu njenge-polyimide, i-cyanate ester kunye ne-bismaleimide nazo zingasetyenziswa.

Ifayibha: Akukho mfuneko.I-Fiber bundle okanye ilaphu lefiber lingasetyenziswa

Izinto eziphambili: akukho mfuneko, kodwa i-foam idinga ukuchasana nokushisa okuphezulu kunye noxinzelelo oluphezulu

Olona ncedo luphambili:

I-1) Umlinganiselo we-resin kwi-arhente yokunyanga kunye nomxholo we-resin ubekwe ngokuchanekileyo ngumthengisi, kulula kakhulu ukufumana i-laminates kunye nomxholo ophezulu wefiber kunye ne-porosity ephantsi.

2) Izinto eziphathekayo zineempawu ezibalaseleyo zempilo kunye nokhuseleko, kwaye indawo yokusebenza icocekile, inokugcina i-automation kunye neendleko zabasebenzi.

3) Ixabiso lemicu yempahla engahambelaniyo liyancitshiswa, kwaye akukho nkqubo iphakathi ifunekayo ukuluka imicu kwilaphu.

4) Inkqubo yokuvelisa ifuna i-resin ene-viscosity ephezulu kunye nokumanzisa okulungileyo, kunye neempawu eziphuculweyo zomatshini kunye ne-thermal.

5) Ukongezwa kwexesha lokusebenza kwiqondo lobushushu begumbi kuthetha ukuba ukulungiswa kolwakhiwo kunye nokubekwa kweemilo ezintsonkothileyo kulula ukufezekisa.

6) Ukugcinwa okunokwenzeka kwi-automation kunye neendleko zabasebenzi

Izinto ezingeloncedo eziphambili:

1) Ixabiso lezinto eziphathekayo liyanda, kodwa alinakuphepheka ukuze lihlangabezane neemfuno zesicelo

I-2) I-autoclave iyadingeka ukugqiba ukunyanga, eneendleko eziphezulu, ixesha elide lokusebenza kunye nezithintelo zobukhulu

I-3) I-mold idinga ukumelana nokushisa kwenkqubo ephezulu, kunye neyona nto ingundoqo ineemfuno ezifanayo

4) Kwiindawo ezityebileyo, i-vacuum yangaphambili iyafuneka xa ubeka i-prepregs ukuphelisa amaqamza omoya.

Usetyenziso oluqhelekileyo:iindawo zesakhiwo sesiphekepheke (ezinje ngamaphiko kunye nemisila), iimoto zomdyarho ze-F1

9. Prepreg - inkqubo engeyiyo i-autoclave

Inkcazo yendlela:Iqondo lokushisa eliphantsi lokunyanga inkqubo yokuvelisa i-prepreg ifana ngqo ne-autoclave prepreg, umahluko kukuba iipropati zekhemikhali ze-resin zivumela ukuba ziphiliswe kwi-60-120 ° C.

Ukushisa okuphantsi kwe-60 ° C ukunyanga, ixesha lokusebenza kwezinto eziphathekayo yiveki enye kuphela;kwi-catalysts ephezulu yobushushu (>80 ° C), ixesha lokusebenza linokufikelela kwiinyanga ezininzi.I-fluidity yenkqubo ye-resin ivumela ukunyanga usebenzisa i-vacuum bags kuphela, ukuphepha ukusetyenziswa kwe-autoclaves.

ukhetho lwezinto:

I-resin: Ngokuqhelekileyo kuphela i-epoxy resin

Ifayibha: akukho mfuneko, iyafana ne prepreg yesintu

Izinto ezingundoqo: akukho mfuneko, kodwa ingqalelo ekhethekileyo kufuneka ihlawulwe xa usebenzisa i-foam ye-PVC eqhelekileyo

Olona ncedo luphambili:

1) Inazo zonke iingenelo ze-autoclave prepreg yemveli ((i.))-((vi.))

2) Izinto zokubumba zincinci, njengemithi, kuba ubushushu bokunyanga buphantsi

I-3) Inkqubo yokwenziwa kweendawo ezinkulu zesakhiwo zenziwe lula, zifuna kuphela ukucinezela isikhwama se-vacuum, ukujikeleza umoya oshushu we-oven okanye inkqubo yokufudumala yomoya we-mold ngokwayo ukuhlangabezana neemfuno zokuphilisa.

I-4) Izinto eziqhelekileyo ze-foam nazo zingasetyenziswa, kwaye inkqubo ikhulile ngakumbi

5) Xa kuthelekiswa ne-autoclave, ukusetyenziswa kwamandla kuphantsi

6) Itekhnoloji ephezulu iqinisekisa ukuchaneka okuhle komgangatho kunye nokuphindaphinda

Izinto ezingeloncedo eziphambili:

I-1) Ixabiso lezinto eziphathekayo lisephezulu kunefayibha eyomileyo, nangona ixabiso le-resin liphantsi kune-aerospace prepreg

2) Isikhunta kufuneka simelane nobushushu obuphezulu kunenkqubo yokufaka (80-140 ° C)

Usetyenziso oluqhelekileyo:amaphiko einjini yomoya asebenza kakhulu, izikhephe ezinkulu zomdyarho kunye neeyachts, iinqwelomoya zokuhlangula, izixhobo zikaloliwe

10. Inkqubo engeyiyo i-autoclave ye-semi-preg SPRINT/beam prepreg SparPreg

Inkcazo yendlela:Kunzima ukukhupha amaqamza omoya phakathi kweeleya okanye iileya ezidlulanayo ngexesha lenkqubo yokunyanga xa usebenzisa i-prepreg kwizakhiwo ezityebileyo (>3mm).Ukoyisa obu bunzima, ukucoca kwangaphambili kwangeniswa kwinkqubo yokubeka, kodwa Yandisa kakhulu ixesha lenkqubo.

Kwiminyaka yakutshanje, i-Gurit iye yazisa uluhlu lweemveliso eziphuculweyo ze-prepreg kunye nobuchwepheshe obunelungelo elilodwa lomenzi, okwenza ukuveliswa komgangatho ophezulu (i-porosity ephantsi) i-laminates engqindilili ukuba igqitywe kwinkqubo enye.I-semi-preg SPRINT yenziwe ngamacandelo amabini e-fiber sandwiching eyomileyo i-resin film sandwich structure.Emva kokuba izinto zibekwe kwi-mold, ipompo ye-vacuum inokukhupha ngokupheleleyo umoya kuyo ngaphambi kokuba i-resin ishushu kwaye ithambe kwaye ifake i-fiber.iqinisiwe.

I-Beam prepreg SparPreg yi-prepreg ephuculweyo yokuba, xa iphilisiwe phantsi kwe-vacuum, inokususa lula amaqamza omoya kwizinto ezibotshiweyo ezine-ply-ply.

ukhetho lwezinto:

I-resin: ubukhulu becala i-epoxy resin, ezinye ii-resin ziyafumaneka

Ifayibha: akukho mfuneko

Izinto ezingundoqo: uninzi, kodwa ingqalelo ekhethekileyo kufuneka ihlawulwe kubushushu obuphezulu xa usebenzisa amagwebu ePVC

Olona ncedo luphambili:

1) Kwiindawo ezityebileyo (100mm), iqhezu le-fiber volume ephezulu kunye ne-porosity ephantsi inokufumaneka ngokuchanekileyo.

I-2) Imeko yokuqala yenkqubo ye-resin iqinile, kwaye ukusebenza kuhle kakhulu emva kokunyanga kweqondo lokushisa eliphezulu

3) Vumela ukusetyenziswa kwelaphu le-fiber eliphantsi kwexabiso eliphantsi (elifana ne-1600 g / m2), ukwandisa isantya sokubeka, kwaye ugcine iindleko zokuvelisa.

4) Inkqubo ihamba phambili kakhulu, ukusebenza kulula kwaye umxholo we-resin ulawulwa ngokuchanekileyo

Izinto ezingeloncedo eziphambili:

I-1) Ixabiso lezinto eziphathekayo lisephezulu kunefayibha eyomileyo, nangona ixabiso le-resin liphantsi kune-aerospace prepreg

2) Isikhunta kufuneka simelane nobushushu obuphezulu kunenkqubo yokufaka (80-140 ° C)

Usetyenziso oluqhelekileyo:amagqabi einjini yomoya asebenza kakhulu, izikhephe ezinkulu zomdyarho kunye neeyachts, iinqwelomoya zokuhlangula

Ixesha lokuposa: Dec-13-2022